MIT’s ‘Implosion Fabrication’ Shrinks Objects to Create Nanoscale Versions

The smaller you want something to be, the harder it is to build. This is the barrier holding back many technologies from batteries to optics, but a new technique developed at MIT could make nanoscale materials easier to produce by shrinking larger designs. The approach uses a type of absorbent scaffold to produce 3D structures .

Thus far, techniques to create tiny 3D structures were both painfully slow and limited in complexity. Most involve using 2D nanostructures etched onto a surface and adding successive layers until you get the desired 3D shape. It’s basically very slow 3D printing.

The technology borrows from an established imaging technique called expansion microscopy; it’s just running in reverse. In expansion microscopy, tissues are embedded in hydrogel and then expanded to get high-resolution scans. The team found they could create large-scale objects in expanded hydrogels, and then shrink them to nanoscale. They call it “implosion fabrication.”

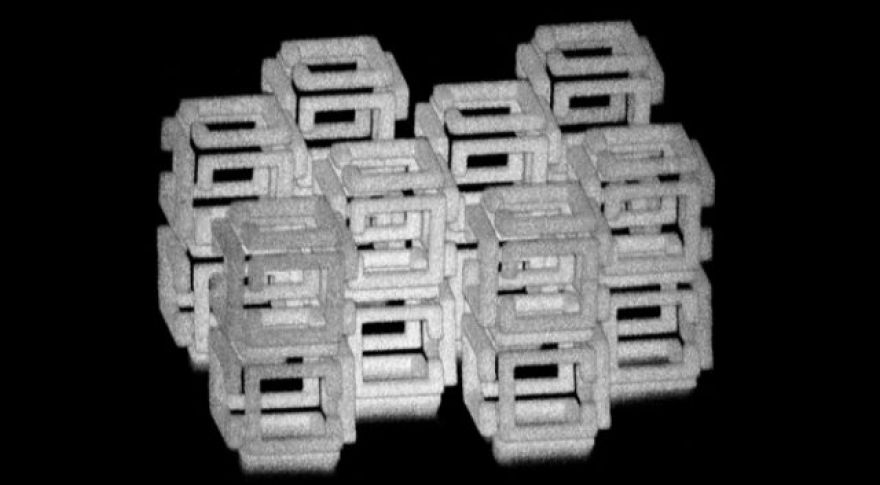

The process starts with a scaffold composed of an absorbent material called polyacrylate. A solution of fluorescein molecules is allowed to infiltrate the polyacrylate. These act like signposts on the scaffold (see below) when exposed to laser light. That allows researchers to attach molecules at any point they want. The molecules can be anything like a gold nanoparticle or a quantum dot.

Everything is still “big” at that point — on the scale of millimeters instead of nanometers. To shrink the construction to the desired size, researchers add acid to the solution. That eliminates the negative charges in the polyacrylate gel, causing it to contract. That drags the molecules along with it, resulting in a 10-fold reduction of length in each dimension for a total 1,000-fold drop in volume.

With current laboratory techniques, the team can take an object with a volume of 1 cubic millimeter with a resolution of 50 nanometers. For larger objects of about 1 cubic centimeter, they can hit a resolution of 500 nanometers. That limit could come down with additional refinements. The team is looking at ways to use this technique to create improved lens optics and nanoscale robotics.

Now read: